Adhesive Options

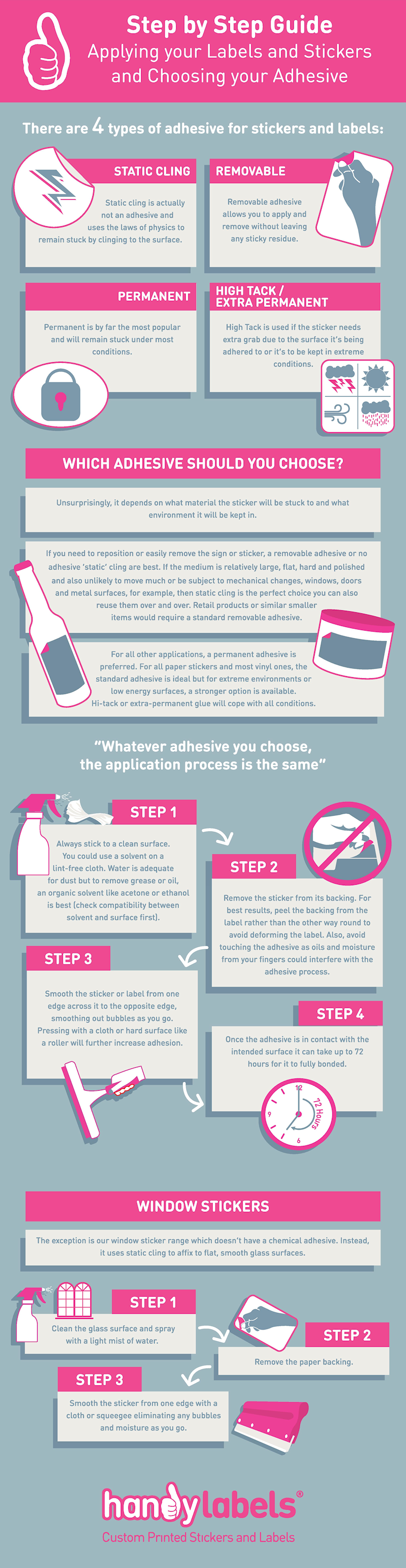

When deciding on which adhesive option works for you, you need to consider if you will be removing the label once it has been applied, and the sort of environment it will be kept in.

Static cling is effective on flat, clean glass surfaces, as its unique adherence properties are optimised for such materials. This characteristic makes it an ideal choice for applications where temporary adherence to glass is required without leaving any residue or damage - like on windows and glass doors. Retail products would require a standard removable adhesive.

For all other applications, a permanent adhesive is preferred. For all paper stickers and most vinyl ones, the standard adhesive is ideal but for extreme environments or low-energy surfaces, a stronger option is available. Hi-tack or extra-permanent glue will cope with all conditions.

There are 4 types of adhesive for stickers and labels:

Static Cling - Static cling is basically no adhesive and uses the laws of physics to remain stuck by clinging to the surface. Its effectiveness is limited to glass and it will not perform adequately on any other type of surface.

Removable - Removable adhesive allows you to apply and remove without leaving any sticky residue.

Permanent - Permanent is by far the most popular and will remain stuck under most conditions.

High Tack (or Extra Permanent) - High Tack is used if the sticker needs extra grab due to the surface it’s being adhered to or it’s to be kept in extreme conditions.

The Sticker Application Process - A Quick Guide

For all adhesive types, other than static cling labels, the application process remains the same:

Step one: clean and dry your product or surface.

Step two: remove the label from the backing sheet.

Step three: smooth the sticker down from one edge to the other.

Step four: allow 72 hours for the sticker to fully bond with the surface.+

Window Sticker Application

This label type uses its static-cling properties to cling to any smooth, flat glass surfaces. To apply them simply clean your surface and spray it with a light mist of water, remove the sticker from the backing and smooth the sticker from one edge to the other, using a squeegee or cloth to eliminate any bubbles. For more in-depth information, please check out our applying stickers 101 guide.